Introduction

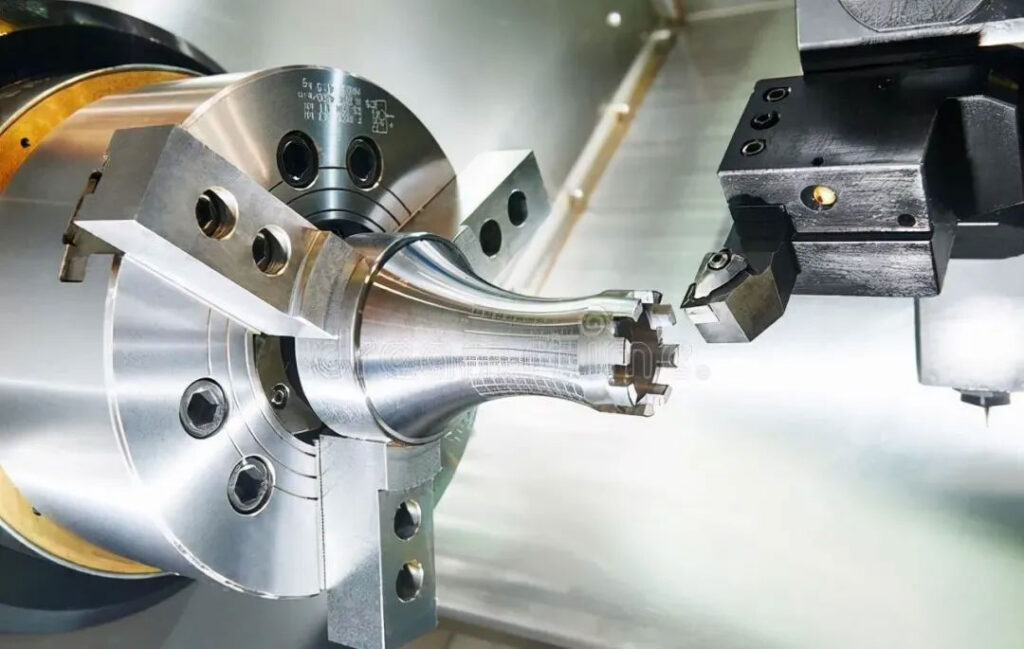

CNC (CNC machine tools) is the abbreviation of Computer numerical control machine tools (Computer numerical control), which is an automated machine tool equipped with a program control system. The control system can logically process programs specified by control codes or other symbolic instructions, and decode them, so that the machine tool can move and process parts.

The so-called CNC machine tools, those without tool magazines are called CNC milling machines, and those with tool magazines are called machining centers. They are also called CNC.

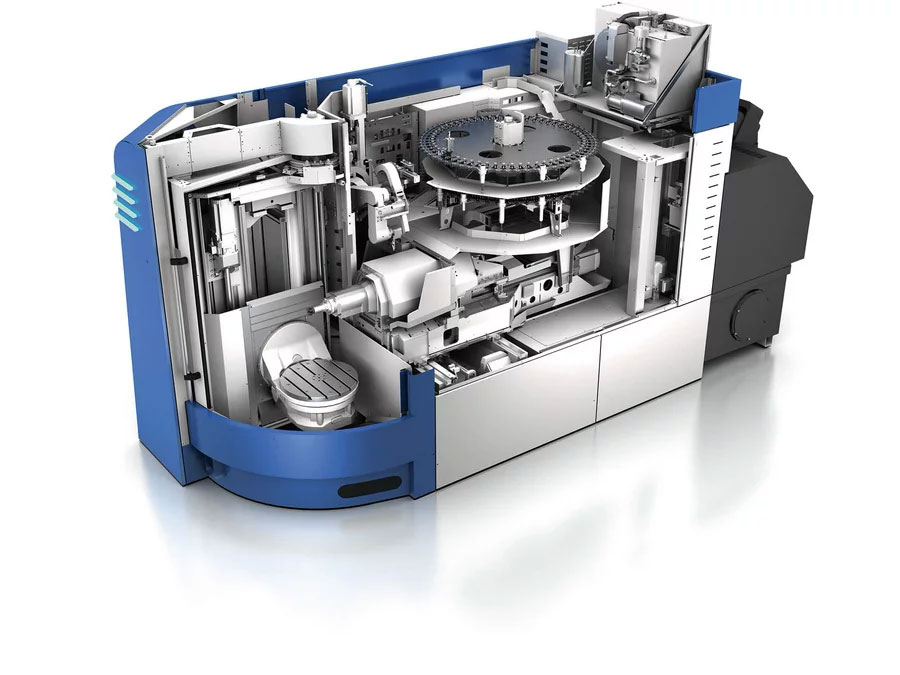

The so-called machining center refers to a CNC machine tool equipped with a tool magazine and an automatic tool change function, which can perform multiple processes after clamping the workpiece once. The machining center is a highly mechatronic product. After the workpiece is clamped, the CNC system can control the machine tool to automatically select and change tools according to different processes, automatically set the tool, and automatically change the spindle speed and feed rate. It can continuously complete multiple processes such as drilling, boring, milling, reaming, and tapping. Therefore, it greatly reduces the time for workpiece clamping, measurement, machine tool adjustment and other auxiliary processes, and has a good economic effect on parts with complex shapes, high precision requirements, and frequent changes in varieties.

Machining centers are usually classified by the relative position of the spindle and the worktable, and are divided into horizontal, vertical and universal machining centers. 1) Horizontal machining center: refers to a machining center in which the spindle axis is set parallel to the worktable, and is mainly suitable for machining box-type parts. 2) Vertical machining center: refers to a machining center in which the spindle axis is set perpendicular to the worktable, and is mainly suitable for machining complex parts such as plates, discs, molds and small shells. 3) Universal machining center (also known as multi-axis linkage machining center): refers to a machining center that can control the linkage change by machining the angle between the spindle axis and the rotary axis of the worktable to complete the machining of complex spatial surfaces. It is suitable for the machining of workpieces such as impeller rotors, molds, cutting tools, etc. with complex spatial surfaces. The following introduces the world’s top ten machining centers. The data in the article is for reference only and is not the only basis for ranking.

1.Yamazaki Mazak CNC Machining Center (MAZAK) – Japan

Global industry status: Mazak is the best supplier of machine tool equipment to Boeing Group and an important supplier to Russian military enterprises.

Japan’s Yamazaki Mazak (MAZAK) is a world-renowned machine tool manufacturer which is founded in 1919. It mainly produces: CNC lathes, compound turning and milling machining centers, vertical machining centers, horizontal machining centers, CNC laser systems, FMS flexible production systems, CAD/CAM systems, CNC devices and production support software, etc. Yamazaki Mazak products are well-known in the industry for their high speed and high precision, and their products are used in various industries in the machinery industry.

Mazak product advantages: Yamazaki Mazak Smooth system adopts Mazak’s seventh-generation CNC system, with brand-new software and hardware configurations, and is a smart platform specifically designed for the Internet of Things era, which can achieve high-speed, high-precision, and high-quality processing. In addition to Smmoth technology, Yamazaki Mazak also has a unique device – a CNC device dedicated to compound processing machines, 5-axis processing machines, machining centers, and CNC lathes.

Japan has many world-renowned machine tool brands, such as Mazak, Amada, Okuma, Mori Seiki, Makino, Mitsubishi, etc. There are many Japanese machine tool companies, and their technology is also leading the world. Take Mazak as an example. Mazak can be said to be the strongest company in the world’s machine tool field. Mazak is the best supplier of machine tool equipment for the Boeing Group and an important supplier of Russian military enterprises. As early as 2013, the Prince of Wales of the United Kingdom personally thanked the Yamazaki family of Japan for their contribution to European industry and manufacturing.

2.GF AgieCharmilles CNC Machining Center – Switzerland (Founded in 1802)

Global Industry Position : GF is the preferred partner of major global customers and is renowned worldwide for its meticulousness and precision.

The products of Swiss GF AgieCharmilles Group are famous for their meticulousness and precision. Whether it is EDM machine tools or milling machining centers, they put product performance, precision and reliability first, and focus on customer needs and processing requirements, and are committed to producing and developing products that best adapt to the market and satisfy customers. At the upcoming CIMT2009, we will focus on industries such as aerospace, tooling and mold manufacturing, and medical devices. GF Group mainly operates three core businesses: pipeline systems, automotive products and AgieCharmilles precision machine tools.

GF includes three divisions: GF Piping Systems, GF Forming Solutions and GF Processing Solutions. Founded in 1802 and headquartered in Switzerland, the company has branches in 34 countries and 137 companies, including 59 production bases. In 2020, it achieved sales of 3.18 billion Swiss francs. Especially in the transportation of liquids and gases, lightweight casting components and high-precision manufacturing technology, GF is the preferred partner of major global customers.

GF’s product advantages: GF processing solution Mikron’s milling technology has always been world-renowned. Mikron machine tools have very advanced thermal stability, which can ensure reliable high precision during long-term processing. Mikron’s unique spindle omnidirectional anti-collision protection technology (MSP) is another highlight, which can prevent the spindle from colliding. Automation solutions can be integrated to bring the production capacity of precision parts manufacturers and mold manufacturers to a new level.

GF Piping Systems: is a world-leading expert in high-quality plastic piping systems. It entered China in 1998 and supplied ground-source heat pump systems for the famous Beijing Olympic Stadium “Bird’s Nest”.

GF Automotive Products: As one of the largest suppliers of light metal and high-strength ductile iron automotive castings in Europe, GF Automotive is a world leader in advanced technology, with GF Automotive products in almost every car model in the world. Its core technology is lightweight design, which allows cost-effective lightweight design to be scaled up, making a huge contribution to energy conservation and emission reduction in global automobiles.

GF AgieCharmilles precision machine tools: the preferred partner for tool, mold and precision parts manufacturers.

3.GROB CNC machining center – Germany (established in 1926)

Global industry position : GROB occupies an absolute leading position in the world in the field of automotive powertrain manufacturing.

GROB Group is a family-owned enterprise operating worldwide, with its headquarters in Mindelheim, Germany, and three overseas production bases in Sao Paulo, Brazil, Bluffton, USA, and Dalian, China. GROB, headquartered in Mindelheim, Germany, is a world-renowned manufacturer of machine tools and production lines. Whether it is standard machine tools, complex production systems, assembly units on cutting lines, or fully automatic assembly lines, GROB’s processes and technologies are always at the leading level.

GROB’s product features: GROB, a German family-owned enterprise, has always been a global leader in high-quality products, advanced technology and reliability, especially in the field of automotive powertrain manufacturing. In addition to consolidating its leading position in the automotive industry, GROB has specially developed the GA series of five-axis universal machining centers for the Asian and Chinese markets, especially its unique “flip-type machining” concept can achieve better chip removal effects, and therefore, can provide excellent flexibility.

For example, the F series of frame structure machining centers are independently developed by GROB and have a series of special features, including four products: G500F, G520F, G700F and G720F; while the G350a and G550a of the access series are the latest models in GROB’s five-axis linkage universal machining center series. These five products have been first launched in the German and European markets and have been well received by users. After all, the most sophisticated instruments in the world are made by Germans.

4.DMG Mori CNC Machining Center – Germany (Founded in 1870)

Global industry status: the world’s leading manufacturer of machine tools and overall technical solutions.

DMG MORI is an international brand machine tool company formed by the reorganization of four machine tool companies, including DECKEL, MAHO AG, Gildemeier, and Mori Seiki, integrating the tradition, precision, and leading technology of machine tool manufacturing from Germany and Japan. Among them, DECKEL is a famous lathe brand, MAHO AG is a very well-known milling machine brand, and Gildemeier produces both lathes and milling machines and is also a company that is very good at marketing planning and promotion. Gildemeier was founded in Germany in 1870. Since 1949, Gildemeier has been listed on the Hong Kong Stock Exchange. In 1994, the company acquired DECKEL and MAHO AG. Since then, the world-renowned “DMG” brand in the global machine tool industry was born. After that, German DMG and Japanese Mori Seiki were integrated, and the strong combination of German manufacturing (DMG 143 years) + Japanese manufacturing (MORI SEIKI 65 years) formed a new global leader in CNC machine tools – DMG Mori Seiki (DMG MORI).

DMG MORI’s product features: DMG MORI’s products are characterized by high precision, high rigidity and humanization. DMG MORI offers a comprehensive CNC machining center product line, from 3-axis machining to 5-axis machining. For example, the DMU 75 monoBLOCK universal machining center. DMG MORI is one of the largest machine tool manufacturers in Europe. DMG MORI continues to bring innovative technologies in aerospace, automotive and additive manufacturing and other fields. It also demonstrates a wealth of digital solutions, covering the entire process from task planning and preparation to production and monitoring. For example, one of DMG MORI’s two key machine tools is the DMU 95 monoBLOCK five-axis linkage machining center. This machine tool uses a cradle-type rotary table, and the spindle speed reaches 20,000 r/min; it uses a three-point support structure to ensure that users can install it quickly and easily; it uses the Siemens 840D system. This machine tool is produced in DMG MORI’s Pfronten factory in Germany, which is the largest five-axis factory in Europe with an annual output value of about 600 million euros.

The advantages of DMG MORI machine tools:

First, it has a three-year warranty period, which is rare in the machine tool industry. The extra-long warranty period also stems from DMG MORI’s confidence in the DMU 95 monoBLOCK; second, in the Siemens 840D system, DMG MORI has integrated many of its own standard functions, such as tool magazine management, on-site operation status display, machine tool processing status display, spindle speed display, etc., and allows users to combine their own experience to make their own APP, and call the self-made APP as a macro program, which greatly improves production efficiency.

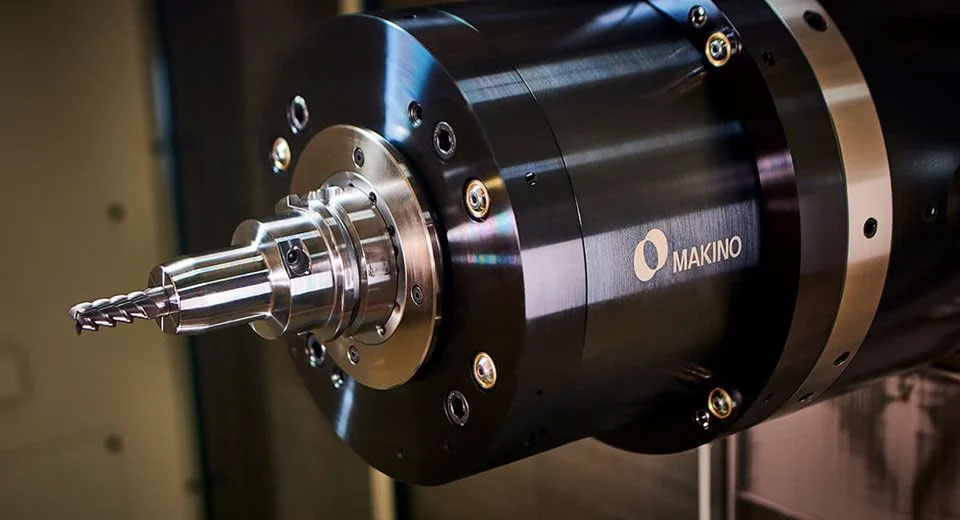

5.Makino CNC Machining Center – Japan (Founded in 1937)

Global Industry Position: Global CNC milling machines and machining centers machine tool manufacturer and industry leader.

The earliest machine tool manufacturer in Japan to produce CNC milling machines and machining centers. Makino machining centers have an excellent reputation in the field of precision molds and parts manufacturing, with corresponding products from three-axis to five-axis, from vertical to horizontal, from micro-machining to large-scale. In recent years, in order to meet market demand, Makino has developed a series of high-precision, high-speed five-axis machine tools. The precision of the five-axis machine tool linkage machining is comparable to that of the three-axis machine tool. Even the iQ500 machine tool with a larger stroke can also ensure that the high-precision requirements of the μm level are met.

Features of Makino products: Makino implements its consistent philosophy globally: high precision, high efficiency and high stability, ensuring that consistently high-quality products are produced in all regions. From the “ace model” that has been popular in the mold industry for more than 20 years – Makino V33i vertical machining center to iQ300 high-precision vertical machining center and then to V80S large five-axis vertical machining center, it fully reflects Makino’s design concept of meeting user needs and its high efficiency, high precision and high performance product features. The application areas of Makino machine tools are mainly molds, parts processing and aerospace. Especially in the Chinese market, the mold industry is the largest application area of Makino machine tools, accounting for more than 60%.

6.Yasuda CNC Machining Center – Japan (established in 1929)

Global industry status: A world-renowned manufacturer of high-precision machine tools.

Many Japanese companies have such outstanding characteristics: the company is not large in scale, but has a very long history and world-leading technology. They are not only one of the pillars of the Japanese economy, but also the “hidden champions” in the industry, such as the high-precision machine tool manufacturer Yasuda Industry Co., Ltd. of Japan.

Yasuda YASDA of Japan is an outstanding representative of high-precision machining center brands, pursuing ultra-high precision of sub-micron precision. “Not seeking the largest but the best” is the basic concept of YASDA. The focus is not on blindly expanding the scale of the enterprise, but on challenging the development of the ultimate products required by the times at any time, so as to organize the development of ultra-high precision machine tools. Its products are suitable for optical molds, semiconductor processing, high-hardness quenching processing (HRC65), high-precision multi-cavity molds, and molds with high finish processing.

Features of YASDA products: YASDA’s machine tools are characterized by high precision and long life. The inherent precision of machine tools and the durability of maintaining this precision depend on the guide rails. YASDA’s guide rails are made of durable hardened steel solid square rails. This type of guide rail is individually ground with high precision and further fine-finished by hand grinding. The joint surfaces of the main structural units (bed, bridge, and saddle) are fixed with bolts. In order to ensure the geometric accuracy and durability of its accuracy, YASDA scrapes and grinds the joint surfaces of the guide rails and the joint surfaces of the structural units, measures with a collimator, scrapes and grinds again, measures again, and repeats the process to ensure its accuracy before fixing the guide rails and structural units.

It is worth mentioning that Japan has an impeccable leading edge in the field of precision instruments and is in a leading position in the world. It also applies this advantage to the machine tool industry. Japan is also the third machine tool industry, manufacturing, and industrial power after the United States and Germany.

7.CHIRON Group CNC Machining Center – Germany (established in 1921)

Global Industry Status: A technological pioneer in the field of global CNC vertical machining centers.

From being a manufacturer of medical devices in its early years to a compressor manufacturer in the 1950s and now a manufacturer of high-speed CNC machine tools, it has always insisted on innovation and maintained its global leading position. For example, the MILL FX800 five-axis high-speed vertical machining center is a true five-axis five-link machining center, especially suitable for the aerospace and automotive parts manufacturing fields.

Chiron GmbH is one of the world’s leading manufacturers of innovative machining centers. The company was founded in Germany in 1921. When it entered the machine tool field in 1957, Chiron positioned itself in the field of batch production, such as in the automotive manufacturing, medical equipment, electronics, and point-of-sale manufacturing industries.

CHIRON Group’s Product Features: It is a global expert in vertical CNC machining centers, turning centers, R&D, manufacturing and turnkey solutions. It is world-renowned for its high-efficiency, high-quality processing of complex workpieces at the lowest unit cost. It is worth mentioning that CHIRON Group has become a benchmark for high performance and high precision in the global machine tool industry, with the world’s fastest tool change system, efficient production solutions and automation technology. For example, the German CHIRON Group vertical machining center has single-spindle, double-spindle, and four-spindle vertical machining centers, which are very different from the tool change methods we usually see. Usually, we see the hat-shaped disc type and chain type. CHIRON Group has an independent manipulator on each tool handle and has a greater improvement in tool change time. It only takes 60 seconds to make a car wheel! Such advanced equipment is mainly used for high-precision parts, such as automobile engines, steering shafts, and other complex parts, especially turnkey projects.

CHIRON Group has four famous brands, including CHIRON, STAMA and SCHERER, three major machine tool brands. Among them, CMS brand is a modification expert. These four brands represent the world’s high-quality precision manufacturing. CHIRON focuses on high-speed and efficient cutting of small and medium-sized parts and non-ferrous metals, and STAMA focuses on heavy-duty and efficient cutting of medium and large parts and ferrous metals. Both companies focus on the field of vertical machining centers, providing single-spindle, double-spindle and even four-spindle processing equipment; SCHERER focuses on the production of inverted lathes, providing single-spindle and double-spindle inverted lathes for turning of disc and shaft parts, while CMS provides machine modification and corresponding overhaul services produced by the group company.

8.Okuma CNC Machining Center – Japan (established 100 years ago)

Global industry status: The world’s largest gantry machining center manufacturer.

Okuma of Japan is one of the few “all-round manufacturers” in the world’s machine tool industry. For decades, it has insisted on independently designing and developing everything from core components (drivers, encoders, motors, spindles, etc.) to CNC operating systems and terminals, truly achieving both hardware and software. In particular, OKUMA’s five-axis machining center can maintain high-precision 5-axis machining for a long time through the synergy of the “5-Axis Auto Tuning System” that maximizes machining accuracy and the “Thermo-Friendly Concept” that maintains machining accuracy.

Okuma is the largest machine tool manufacturer in Japan and the largest gantry machining center manufacturer in the world. It has a history of more than 100 years and produces various CNC lathes, turning centers, vertical, horizontal, gantry (pentahedron) machining centers, CNC grinders, etc. Okuma is not only a world-renowned CNC machine tool manufacturer, but also began to develop Okuma’s own CNC system – OSP CNC device as early as the 1960s. It produces more than 7,000 CNC devices and about 30,000 spindles and servo motors annually, which once ranked around 5th in the world. The OSP system is not only advanced, stable and reliable, but also practical and easy to operate. It is completely integrated with the machine tool and truly achieves mechatronics.

Okuma’s product features: Okuma products are famous for their good rigidity, high cutting efficiency, high precision, long life and easy operation, and are well received by users all over the world. Okuma CNC system is an industry benchmark in Japan. It is a comprehensive and practical CNC system. Many functions are modular (i.e. optional functions) and are highly targeted. Usually, when using a machining center for machining operations, it is hoped that the machining operations will be performed in a unified machining coordinate system. However, in some machining situations, using some coordinate transformation techniques combined with subroutine call instructions can make machining programming simpler and easier.

The precision of Japanese machine tools is well-known around the world. For example, from the shape of the Boeing 787 passenger plane in the United States, many people find that its wings are obviously different from most civilian aircraft. What is surprising is that this beautifully curved wing and the fuselage of the aircraft are not made in the United States, but are made by high-end machine tools in Japan. The strength of Japanese high-end machine tools lies in the words “ultra-high precision”, because the higher the degree of precision means that the products it produces are more perfect, and the more they can break through the bottlenecks encountered in scientific research in practical applications. The powerful Japanese machine tools almost occupy half of the world by themselves. In fact, Japanese high-end machine tools have become the third powerful country in the world to establish a machine tool industry after the United States and Germany.

9.Hermle CNC Machining Center – Germany (established in 1938)

Global industry status: Hammer is a global expert in small and medium-sized five-axis precision machining.

One of the most famous machine tool manufacturers in Germany. Hermle’s five-axis vertical machining centers are in a leading position in the international market. The factory is located in Gosheim near Stuttgart, Germany. Today, more than 20,000 universal milling machines and machining centers produced by Hermle are used worldwide. Its reliable product quality and excellent after-sales service ensure that Hermle has become a trusted partner of customers.

Hermle is an expert in small and medium-sized five-axis precision machining. Its products have obvious advantages in complex surface machining, negative angle machining, high-precision machining and high-speed machining. Hermle ranks first in the market share of five-axis machine tools for small and medium-sized mold manufacturing in Germany. Solve problems for customers: The high rigidity of the machine tool is particularly suitable for the machining of thin-walled parts.

Hermle’s product features: Hermle, Germany, focuses on milling and excellent results in everything it does. Therefore, “Milling” has become the slogan of Hermle AG. It represents a powerful, highly innovative machining center that occupies a leading position both in Germany and internationally. It also represents a large and tight sales and service network. It is worth mentioning that the worktable of Hermle products has a large swing angle and good dynamic performance, which is suitable for complex curved surface processing (including negative angle processing). The machine tool’s high geometric accuracy and position accuracy are suitable for high-precision parts processing, especially parts processing with high hole position accuracy (parallelism, repeatability). The machine tool has stable performance and good long-term accuracy retention.

Hermle produces about 1,000 machining centers annually, 80% of which are five-axis machining centers, so its advantage is also in 5-axis machining. Machine tool manufacturing is higher than the DIN/ISO 10791 standard in many aspects. Whether it is high-demand milling or milling-turn synchronization, it can be achieved with the integrated swing axis and rotary axis, together with the high-efficiency torque motor, so it has great advantages in flexibility.

10.Haas CNC Machining Center – United States (Founded in 1909)

Global industry position: Leader in the global small and medium-sized machining market

Haas Automation is one of the world’s largest CNC machine tool manufacturers, with a world-leading production base in Oxnard, California. As early as 2006, the annual output of Haas CNC machine tools reached more than 12,500 units, a milestone in the CNC machine tool industry. In the world’s machine tool industry, the United States is still at the world’s top level. In fact, throughout the 20th century, American machine tools have always been leading, but in the 1970s and 1980s, Japan’s technology surpassed the United States. However, the United States has not lost its foundation in machining, especially after the emphasis on machining in the 21st century, the technology has surpassed Japan, or at least maintained a level of parity with Japan. Representative machine tool companies in the United States include: Gleason Machine Tools (a leader in the field of gears); Haas Machine Tools (CNC machine tools); Hardinge Machine Tools (lathes and fixtures).

For the field of American aviation engines, the most important one may be the Hardinge machine tool. Because it is the leader in the global small and medium-sized machining market, it occupies almost 80% of the market share in Europe and the United States. Especially in the military field, it has many applications. Almost all small precision machining in the military field in Europe and the United States is handled by this machine tool factory.

It is worth mentioning that CNC machine tools were originally developed by Americans. Whether it is Cartesian coordinate system or virtual axis system machine tools, Americans are far ahead of the world’s machine tool industry. For example, Greenson Machine Tools was once the king of surface processing and gear technology. Cincinnati, the creator of the world’s first five-axis linkage machining center. For example, Japan’s Mitsubishi Heavy Industries only uses Cincinnati machine tools to manufacture key parts. For example, Rolls-Royce aircraft engine combustion chambers and Musk Dragon spacecraft thrusters cannot be separated from Cincinnati. For example, Hurco in the United States was once the leader of global intelligent CNC machinery, especially in water jet processing. The CNC honing machine of Sunergy in the United States is also one of the best in the world.

Haas’ product features: Haas VF-1 vertical machining center has established an industry benchmark for high quality and high cost performance. The excellent Haas CNC system makes the operation of the vertical machining center handy, and is equipped with intuitive functions that other brands of machine tools do not have. It is worth mentioning that Haas is also the only one in the machine tool industry that truly achieves completely transparent prices. Haas uses its own developed system, and the latest system is Series 16; the Haas system is compatible with FANUC and Mitsubishi programs.